This laurel berry soap, or Aleppo soap copycat recipe, is a modified Castile soap that is mild, conditioning, and great for a number of skin conditions.

Why would you want to make Aleppo soap?

Aleppo soaps are one of the most prized, and most expensive soap bars, that you can find.

These soaps are said to help with a number of skin conditions like acne, eczema, psoriasis, and other dermatitis types. Some people use it on their hair and say that it helps with dandruff and other scalp conditions. It’s a mild soap that soothes the skin and may have natural antibacterial and antifungal properties.

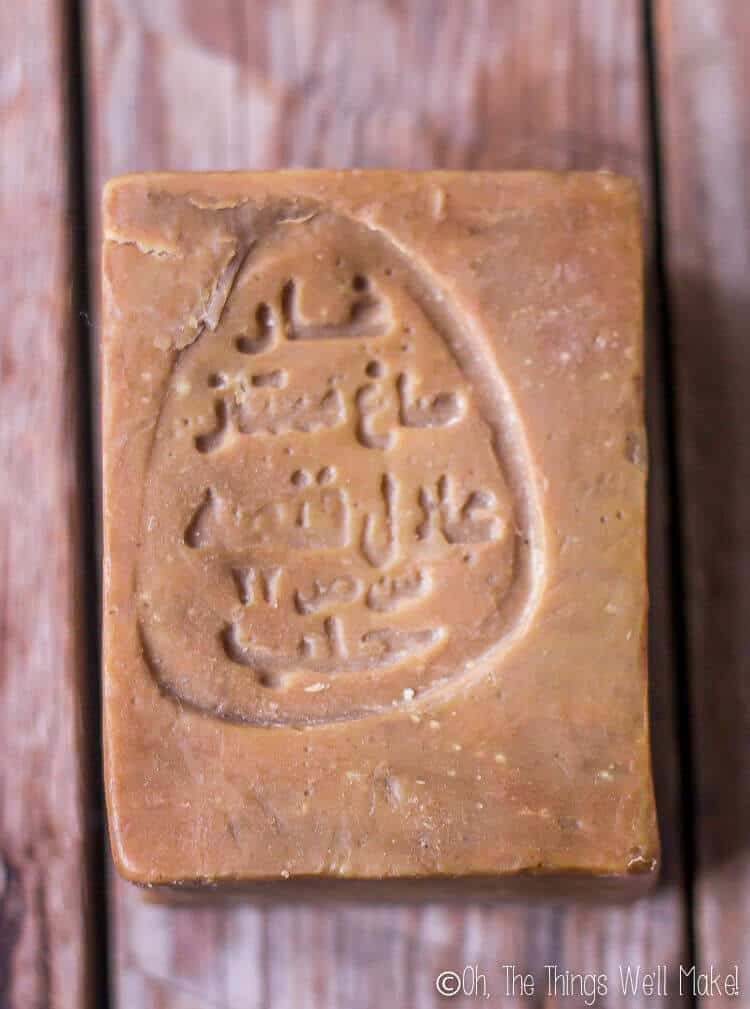

Here is an example of a bar of Aleppo soap sold on Amazon:

What is Aleppo Soap?

Thought to be one of the first soaps made, Aleppo soap is a modified Castile soap made from olive oil and laurel berry oil. I call it a modified Castile soap because it isn’t made with 100% olive oil like my pure Castile soap recipe.

Laurel berry oil is a more expensive oil, and the price of a bar of Aleppo soap usually depends upon the percentage of laurel oil used. Soaps with a higher percentage of laurel oil tend to be darker in color and more prized. Most Aleppo soaps have between 5 and 30% laurel berry oil, but you can find them with other percentages too.

Being a Castile soap, it is usually cured for long periods of time to allow it to harden and for its quality to improve. During the curing time, the soap usually develops a golden hue on the outside while retaining it’s beautiful green color on the inside (which can be seen if you cut a bar of Aleppo soap in half). You can find photos of bars of Aleppo soap that have been cut in half in this article about Aleppo soap benefits.

Aleppo soap is associated with the city of Aleppo, Syria, where they have continued to make the soap for what is said to be thousands of years. Unfortunately because the war in the region has forced many of the soap makers to leave their businesses behind, it is becoming increasingly more difficult to buy authentic Aleppo soap made in Syria.

Some of the Aleppo soap makers who were forced to leave their city are trying to build their businesses again in new locations.

How is Aleppo Soap Made?

Aleppo soap is normally made using a type of hot process technique. It probably doesn’t use the hot process method as we know it today, though, but rather uses a boiled soap process in which the oils are boiled with the lye over a number of days. There is a bit of confusion outside of the Aleppo soap-making community about the exact technique and why the soap is boiled for so long.

After reading discussions in a number of forums, my guess is that part of the reason for boiling the soap for so long is that traditionally ashes were used to react with the oils, which is much different than making soap with a commercial lye. When using ashes, it is impossible to be able to calculate exact amounts needed to complete the saponification process of the soap.

It is very possible that part of the boiling process uses salt water as a sort of purifying step. I’ve read that salt water was often used in the production of Aleppo soap, so it would make sense that it may have been used in a salting out process which is sometimes used to rinse away any excess lye that may be left in soaps.

I found this thread in a forum with an explanation of the process of making Aleppo soap that would support those ideas.

Once the soap is formed, it is poured and spread over the floor of large rooms, where it is spread out to the desired thickness, and then smoothed. It is later stamped and cut, and the formed bars of soap are stacked and allowed to cure for several months.

This video shows the interesting process of making Aleppo soap:

While some of the soap makers seem to continue to use the same traditional methods for making Aleppo soap, others now use a more “normal” hot process or a cold process technique for making it.

What is laurel berry oil?

Laurel berry oil is an oil that is extracted from the fruit of the bay laurel tree.

What are laurel berry oil benefits?

This prized oil is known most for being used in Aleppo soaps, but also has muscle relaxant properties which makes it a great oil for massaging in areas of sore joints and muscles. It may also help improve arthritis symptoms.

Laurel berry oil is a soothing oil that helps improve skin and scalp conditions. Because it is said to help with dandruff and thinning hair, many people swear by using Aleppo soap on their hair. (I personally haven’t tried it as I haven’t found that my hair reacts well to using (any) soap on it.)

Apart from being known to improve skin conditions such as acne, eczema, rosacea, psoriasis, it’s antifungal and antibacterial properties may also improve fungal infections and bacterial dermatitis.

Apart from it’s other benefits, in soap, the laurel berry oil helps add a bit more lather to an otherwise very low-lather Castile soap. (Soaps made with only olive oil are very conditioning, but are also low lather soaps that aren’t as high cleansing as many other soaps.)

Watch me make this laurel berry soap

Why did I choose to make a cold process laurel soap?

Because we are using modern methods and a commercial lye for making our laurel soap, there is no need to complicate the process with boiling it down to remove excess lye. We can calculate the recipe to be superfatted, meaning that we will use more oils than what are needed to react with the lye in our recipe. My recipe below was calculated with a superfatting percentage of 5%. This means that we will end up with some unreacted oils in the soap that are conditioning for our skin and hair, and that our soap won’t have any unreacted lye in it.

While we could use a modern hot process technique, I don’t see any benefit to choosing it. A hot process technique cooks the ingredients to speed up the saponification process, meaning that the lye and oils have fully converted to soap before being poured into the molds. The problem with this method is that you end up with a thicker mixture that is more difficult to work with and that doesn’t pour or smooth as well in your molds. As we won’t be stepping on our soap to smooth it out as the Aleppo workers do, I prefer to use a cold method process to get a nice looking bar of soap.

Some people choose to use hot process methods in the hopes that they can use their soap sooner. I’ve found, though, that all soaps benefit from a curing process. During the curing process, the soap gets harder and other chemical processes continue. This is especially true of pure Castile soaps and other soaps with a high percentage of olive oil like Aleppo soaps. Note that Aleppo soap, despite being made with a hot process of sorts, is cured for several months (I’ve read between 9 months and a year) before being sold to the public.

Why is my soap green and not golden like the Aleppo soap?

During that curing process, the soap is said to change from green to golden on the outside. While I did wait a couple of months to take pictures and post them with this recipe on the blog, I haven’t waited anywhere near the 9 months to a year that Aleppo soaps are said to cure before being sold.

Being impatient, I tried a bar of my soap and have to say that I already really like it. Without any additives or scents, it has an unusual medicinal, but pleasant, scent that I actually quite like. I’m excited to see how it changes with time, though, and will update this post in several months with my findings.

It will be interesting to see if my soap takes on a similar golden color to the Aleppo soap I bought from the store. I’m also looking forward to seeing if they behave similarly when used. Only time will tell…

Laurel Berry soap (Aleppo Soap Copycat Recipe)

Materials

- 450 g olive oil

- 150 g laurel berry oil

- 228 g water

- 78 g lye aka. Sodium hydroxide (NaOH)

- 18 g fragrance or essential oils optional- I didn’t use any

Instructions

- Weigh out the lye and the water in separate containers. I now usually use stainless steel bowls for this step. (Other metals may react with the lye, while some plastics may be melted and some glass bowls may crack from the sudden heat of the chemical reactions when you mix the water and lye together.)

- Add the lye to the bowl of water. (Do not add the water to the bowl of lye.) Stir the water and lye together thoroughly in a well ventilated area. You will notice that the lye solution will heat up and get cloudy. It will also give off fumes that you should avoid inhaling.

- Allow the lye solution to set in a place where it won’t be disturbed by animals or small children while you measure out the oils.

- Weigh out the olive oil and laurel berry oils in a large bowl. At this point you can use ceramic, glass, stainless steel or plastic.

- Pour the lye mixture into the oils and gently stir them together. It’s OK if the lye mixture is still warm.

- Once you have thoroughly combined the lye solution and oils, you can begin to blend them with an immersion blender. As you blend the ingredients together, they will begin to thicken and become more opaque.

- Your mixture will thicken to the point of looking like a creamy salad dressing or light mayonnaise. This point is called “trace” in soap making. At this point you can add in any extra fragrances, essential oils, or other additives as desired.

- Pour the soap mixture into molds and allow to harden for a couple of days before unmolding. (You can unmold as soon as you feel the soap is hard enough. The amount of time will depend upon the temperature of your environment, humidity, molds used, etc.)

- Cut the soap into bars as needed. Don’t wait too long to cut the bars of soap or the soap will get too hard and brittle to cut easily.

- Allow the bars of soap to cure for at least a month before using it. Ideally you should wait several months. Olive oil based soaps like this one are normally allowed to cure for several months before using them. The soap will harden and improve with time.

Español

Español

How to Make Celery Salt and Celery Powder (& What to do with Celery Leaves)

How to Make Celery Salt and Celery Powder (& What to do with Celery Leaves)

arra

Hi, thank you for sharing I can’t wait to try this.

Were you able to create a new version recipe with more laurel oil?

Tracy Ariza, DDS

I never got around to it, but I should give it a try as I have some oil that will start to go rancid soon if I don’t use it.

Kristina Whittington

Can Laurel Berry be used to make lotion and if so what percentage would be safe and non-irritating?

Tracy Ariza, DDS

Hi Kristina,

That’s a great question!

I’ve actually been meaning to try it myself. Laurel berry oil is supposed to be great for all kinds of things because it has anti-bacterial and antifungal properties. It may help with acne, dry skin, eczema, rashes, psoriasis, rosacea, fungal infections, and may even help with muscle soreness and sore joints.

I’m not sure if there is any limit to how much you can use. It’s a carrier oil and not an essential oil and I think it’s generally OK to use however you like. I’ve rubbed it into my skin without issues, and I think it’s suggested that you use it full strength for joint pain. So, you can probably use it at whatever strength you want in a general lotion.

Gregg

Hi! A question… Do you heat the oils to combine them with the lye solution at any specific temperature?

Tracy Ariza, DDS

Hi Gregg,

I normally add the lye solution while still warm and allow that to slightly heat the oils. I don’t take the temperature.

Some people believe that temperature is important in the soap making process, but I’ve done a lot of experimentation and haven’t found it to make much of a difference. The warmer your ingredients are, the quicker the process will move along, though.

Because the laurel berry oil is more of a solid, you could gently heat it to melt it. That will help ensure everything combines well- and that the thickness of the oil doesn’t confuse you into thinking you’ve reached trace before you really have.

Some people actually prefer to “hot process” Castile soaps (cooking the mixture during the soap making process) to try to improve their lather. I’ve been planning on making new batches of this soap and the pure Castile soap using both methods to see if, indeed, it makes a big difference in the final soaps.

For now, I just “cold process” as shown here because it’s quicker, less messy, and generally makes for a smoother soap.

Valle Moreno

I have made this soap twice following exactly the same recipe: 25% of laurel berry oil and CP. I don’t know why my soap is not green at all but a yellowish/creamish color. I used a six cavities silicon mold. I am thinking that maybe using an extra virgin olive oil (that I usually avoid in soaping for its strong green color) could be a good idea and using a loaf mold (that keeps the heat better) could be a good idea as well. My husband and I looooooove this soap anyway but, you know, you feel like it is more “Aleppo style” if it is green.

Tracy Ariza, DDS

Hi Valle,

I think most of the soaps for sale actually use an even higher percentage of the laurel berry oil. I sort of avoided doing that in my first trial because the oil is so pricey in most of the world. I do normally use extra virgin olive oil, though, as it’s what I normally have at home. (I live in Spain where high quality olive oil is relatively inexpensive.)

I’ve been really tempted to make a new soap using a higher percentage of laurel berry oil- and trying to hot process it (as most traditional laurel berry soaps are made) just to see what the outcome is. When I get to it, I will definitely post the update (and information about what recipe I end up making).

Leslie

I used poppy seeds and mixed in almond , argan, neem, and jojoba oil instead of using just olive oil. The laurel berry oil is wonderful stuff! Best soap I’ve ever made!

Lynn

Hi. Thank you for the great video. Just looked up the cost of laurel berry oil and it is about £18 for 150 grams ( plus postage) which would make the soap very expensive to produce! Am I looking at the right one?

Tracy Ariza

Unfortunately, yes!

I can be a pricey oil. 🙁

Caroline

Hi Tracy, I wonder if you’ve ever tried making soap with ground up bay leaves in it instead of using the laurel berry oil? I’m in Australia and the oil is rather expensive to buy here, but I wonder if having the actual leaves in a basic soap base would also be nice? I suppose it would add a nice exfoliant if nothing else! I’m enjoying your website, thanks for sharing so many great things 🙂

Tracy Ariza

Hello Caroline,

No, I’ve never tried it. The laurel berry oil comes from the berries themselves and not the leaves so I’m guessing the properties would be quite different.

Yes, you’re right about it perhaps being a nice exfoliant. It would also give the soap some color. It might be mottled, though, unless you can get the leaves to be a fine powder. I’ve used paprika to color soap and it does a nice job of giving a nice, uniform color. ?

Good luck with whatever you decide!

Teresa Smith

I just made this recipe today! I had been wanting to make it for a long time! Can you update us on how yours has aged? Pictures? Or have you used it all by now?

Tracy Ariza

Hi Teresa,

Sure! I’ve been going through and updating all of the posts on my blog lately, but haven’t gotten to the soaps because I’ve been working on the seasonal stuff first. Let me try to get some pics this week. I want to show updated pics of the glycerin soap too!

This one has become golden on the outside. It’s no longer green. It isn’t as dark as the ones I’ve bought, though.

I think I may try to make a second version of this soap- hot process it and use more laurel berry oil. I think it would make it more like the original.

It’s a very mild soap- very much like most Castile soaps. It doesn’t have a lot of lather compared to others, but it’s very mild.

I’m really tempted to cut one in half and see if mine is still green on the inside (as they say Aleppo soaps are- but I haven’t tried cutting one of those either).

Perhaps I’ll do that and show pics of both!

Pierre

Hi Tracy,

what is the size of your mold you used in the video.

Thank you

Tracy Ariza

Hi Pierre,

The mold in the video is 20cm by 9cm with a height of 6cm.